We wish you a merry x-mas

Dear customer

It’s that time again: Christmas is just around the corner.

We would like to take this opportunity to wish you a merry and blessed Christmas

as well as happiness and success for the coming year 2026.

Below are our opening hours for the coming days:

Closed:

24.12.2025 – 02.01.2026

Last shipping day:

19.12.2025

Open again:

05.01.2026

Stay healthy – Your

Your partner for industry and commerce | Reliable – Competent – Innovative

Technical plastic, metal and hybrid products

Are you looking for technical standard and norm parts or special solutions for your various applications?

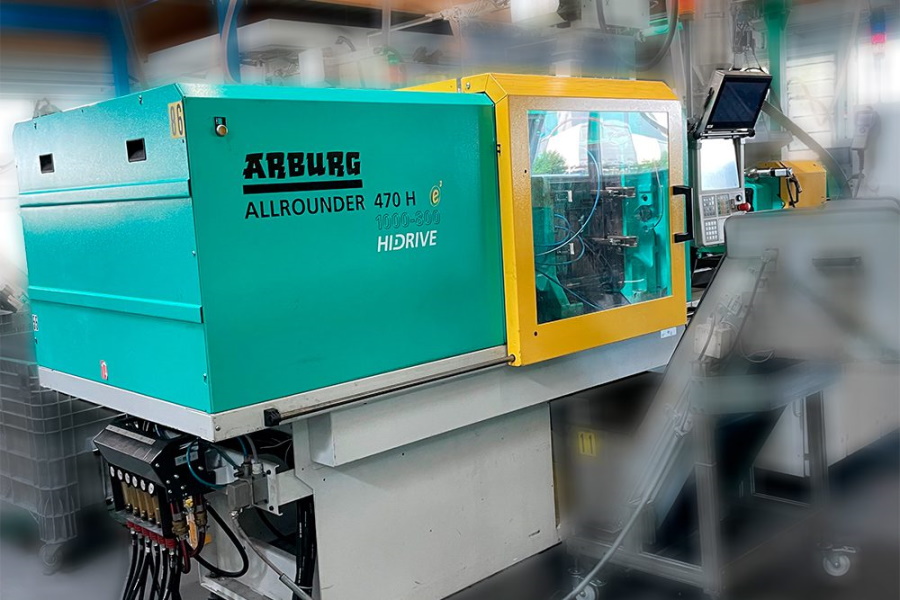

With b-plastic, you are choosing a competent and flexible partner with over 60 years of experience in the production of technical plastic articles using injection moulding. Our family business is characterised by quality and cost awareness and is focused on sustainability…

With our team of around 50 well-trained and committed employees, we are constantly working on new ideas and concepts to improve our range and our processes. A constant exchange of knowledge in close cooperation with our specialist departments, the maintenance of short lines of communication and respectful and motivated cooperation characterise our actions.

We are looking forward to your visit in our B2B-Shop or simply to your personal call.

Quality, environment and compliance standards

In focus – products, applications, guides and more

From the product idea to delivery