Category: General

Furniture glides guide b-plastic

In our guide to furniture glides, we want to focus your attention on the functionality of furniture in relation to floor types. We will introduce you to the different types of furniture glides and provide information about their preferred areas of application, the materials used and the floor coverings they are suitable for. We hope this will give you a better overview of which glide is right for your needs.

Furniture feet, also known as floor glides, chair glides or simply furniture glides, play a key role in ensuring the longevity of furniture and protecting a wide variety of floor coverings.

Whether you are a furniture manufacturer, furniture designer, refurnisher or interior designer, our comprehensive guide will help you select the right products from our extensive range of furniture glides, furniture feet, height adjustment elements and caps.

By combining design, functionality and technical details, we offer a wide range of solutions that contribute to the longevity of furniture while protecting floor coverings. If you cannot find a suitable product in our standard range, we are happy to assist you with our decades of experience in the development, manufacture and distribution of furniture glides as your partner for customised solutions.

Requirements for furniture glides

Furniture glides must be integrated into design concepts and at the same time fulfil the requirements for durability and functionality. They often need to provide unobtrusive and reliable service for the entire service life of the furniture. Whilst furniture that is not moved or subjected to a lot of stress is rather uncritical when it comes to selecting suitable furniture feet, mobile furniture and chairs in particular pose a particular challenge. Here there is an intense field of tension between chair, floor covering and use, in which the furniture glide must find its optimum role.

The main requirements in this area of tension are

- Protection of the floor covering: No scratches or other damage.

- Resistance of the glider: Against dirt or abrasive sealing of the floor, e.g. with hard materials.

- Comfort: Easy and quiet movement of the chair, without unwanted slipping.

- Robustness: Tolerance of tilting, dropping or improper use of the chair.

What can furniture sliders do and what not?

Furniture glides or chair glides are wear parts and must be regularly maintained and inspected as a preventive measure – especially with sensitive floor coverings and with intensive use of the chair. There are no universal glides that are ideal for all applications and floor conditions. There are indeed gliding surface materials that can be used on all floor coverings. But there is a conflict of objectives between durability (e.g. PTFE, felt) and functional incompatibility (e.g. TPE-U/PUR = excellent adhesion or PTFE = excellent sliding).

The application and durability of the chair glider essentially depend on the following factors:

- Installation surface: The nature and size of the sliding surface in relation to the load capacity (person weight and chair weight).

- Material selection: The correct selection of the gliding material to match the floor covering, the desired comfort and the use of the chair.

- Use: In schools, event spaces or mass seating, additional requirements may arise due to intensive use or vandalism, which can affect the chair and gliders.

In this context, it should be noted that the potential risk of wear to the glider or its sliding surface increases quadratically with decreasing diameter. As the diameter of the gliders decreases, the pressure load on the floor also increases quadratically. These potential risks must be taken into account when using chair gliders with relatively small sliding surfaces. For example, in the case of tubular steel chairs, where, due to design concepts or cost and weight savings, round steel tubes with a small diameter or even tapered, hydraulically formed steel tubes with a small diameter are used. In addition, the attachment and firm hold of the chair gliders can pose a risk with decreasing chair tube diameter. This should be taken into account and checked when selecting a suitable glider.

This is less critical for cantilever chairs or tubular steel chairs without standing legs with smaller steel tube diameters (18-22 mm) if the sliding surface can be dimensioned to be sufficiently long.

Designs of furniture sliders

In correlation to the development of different chair and chair frame types and application requirements, various chair gliders have become established in recent decades. Gliders differ fundamentally in their construction, the way they are mounted on the furniture or chair, and the material of their sliding surface.

Combination examples of chair frames and chair glides

with wooden legs

made of round tubing

with flat-skid frame

with C-frame

with sled base frame

with straight legs

with slanted legs

with slanted legs

Articular glider with PA sliding surface

Articulated gliders with PE sliding surface

with four-legged frame

with turnstile frames

Structure of furniture glides

One-piece furniture glides

One-piece glides are usually more cost-effective and allow for flatter and less obtrusive designs. In most cases, the quality of the attachment to the chair determines the size, unless design and functional aspects are the main focus.

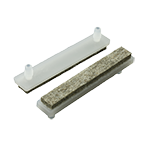

Multi-part furniture glides with a firm bond between the base body and the gliding insert

Multi-part gliders are significantly more elaborate and therefore more expensive, but they allow for better adaptation to different floor coverings without having to accept any loss of strength and stability of the furniture gliders.

Multi-part furniture glides with form-fitting connection between base body and gliding insert

Types of furniture glides according to how they are mounted

Furniture glides and their different types of mounting

The finished furniture sliders are mounted differently on the respective furniture. Here are some examples:

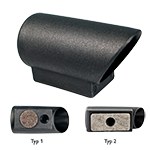

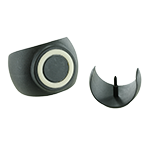

Articulated glides

By screwing directly into a pipe thread or in combination with an additional threaded plug

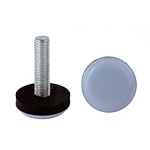

Angled glides

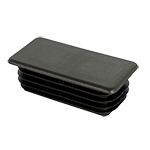

Inserted into the pipe, if necessary with additional fixing using a countersunk screw

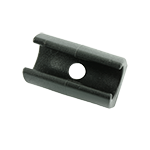

Clamping shell glides

By pressing over the tube. Positioning by means of the existing sliding pin and fixing by means of the frame bore and fastener.

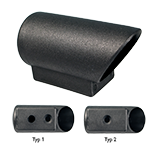

Shell glides

Secure positioning using pins on the glider and fixing through frame holes

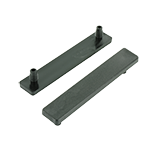

Skid glides

Positioning and fixing via two frame holes using clamping pins. Alternatively, with two additional connecting elements.

Furniture gliders – materials and designs

The glide inserts and the glide coating determine the gliding ability, the wear and the potential impact on the floor. Depending on the area of application, our range includes various materials and forms. Some glide inserts are self-adhesive and can be mounted directly on the furniture.

Example

Material

Felt punching part (natural or coloured)

- wool felt

- industrial felt

Mounting with body

- pressed-in

- plastic-moulded

- snapped

- glued-on or stuck-on

- welded-on (friction welding)

Properties

- floor-protecting

- Sound-absorbing

- noise-reducing

Field of use

- wooden floors

- tiles

- stone floors

Suitable designs

Material

Metal-sliding surface

- stainless steel

- chromed

- nickel-plated

Mounting with base body

- wrapped around the glider

Properties

- robust

- good sliding

- no or little abrasion

Field of use

- hard wooden floors

- carpets

Suitable designs

Material

PUR-punch insert in red-brown

- PUR

Mounting with base body

- glued-on or in (self-adhesive)

Properties

- slip-resistant

- sound-absorbing

Field of use

- stone floors

- wooden floors

- plastic floors

- linoleum floors

Suitable designs

Material

PTFE-gliding insert (natural colour or dyed)

- PTFE-slip film

- film carrier

- rubber/EVAC

Mounting with base body

- pressed-in

- glued-on or in (self-adhesive)

- nailed-in

- screwed

Properties

- excellent sliding

- sound-absorbing

Field of use

- carpets

- wooden floors

- linoleum floors

- plastic floors

Suitable designs

Material

Hard plastic insert (natural colour or dyed)

- PA

- PP

- POM

- PE

Mounting with base body

- pressed-in

- plastic-moulded

- snapped

- welded-on (friction welding)

Properties

- robust

- good sliding

- no or little abrasion

Field of use

- carpets

- wooden floors

- tiles

- stone floors

Suitable designs

Material

soft plastic insert (natural or coloured)

- TPE (-U, -V, -E)

- PVC(-P)

Mounting with base body

- pressed-in

Properties

- slip-resistant

- sound-absorbing

Field of use

- wooden floors

- tiles

- stone floors

Suitable designs

Material

one-piece glides (natural or coloured)

- PA

- PE

- PP

- PVC

- POM

- nickel-plated steel

- Filz

- PUR

Mounting with base body

- no mounting

Properties

- Depending on the material, different sliding properties from good sliding to slip-resistant.

Field of use

- Various floor coverings depending on the material

Suitable designs

TPE-U has the greatest stopping power and a very long service life on a wide variety of floor types.

PTFE has the greatest sliding effect (static and sliding friction) on a wide variety of floor types.

Some of the mounted glide inserts can be replaced with new ones with little effort. It is often cheaper or more sensible to replace the glider than to replace glide inserts in gliders designed for interchangeable glide inserts. In order to ensure the most universal use possible, natural-coloured gliding surfaces are recommended. This also avoids a possible risk of colour migration if the floor and/or gliders contain vinyl (PVC, EVA, etc.). When wet cleaning the floor, it is recommended that furniture with felt glides or steel glides (nickel or chrome plated) should only be put back on the floor once it is completely dry. The material of the gliding surface and the floor cleaner must be compatible and must not interact.

Basic information on choosing the chair glider and the sliding material

The choice of gliding insert material depends on the demands placed on the floor covering and the desired comfort. To make a suitable choice of glider, it is advantageous if the floor covering manufacturers specify suitable or compatible gliding materials for their products and the minimum gliding surface per chair or chair leg.

When it comes to the comfort requirement for low noise generation, it should be noted that soft materials (felts, elastomers, thermoplastic elastomers) wear significantly faster with decreasing hardness.

When comfort is required in the form of particularly easy movement, it should be noted that the materials PTFE and ultra-high molecular PE or irradiated ultra-high molecular PE cannot be processed into moulded parts using standard thermoplastic methods, but are generally available as semi-finished film products or sintered pressed parts for further processing into firmly bonded composite moulded parts. The wear resistance of the available and processable films is limited, so that despite the low friction and the resulting low abrasion during intensive use, only an average lifespan can be expected.

Extreme demands by users or the type of use usually occur in schools and in mass seating with stacking chairs. Here, only a good floor cleaning in connection with regular inspection and maintenance helps. Vandalism is not uncommon. Chair gliders cannot meet these requirements in the long term. On sensitive floors, natural-coloured glides can ensure that the abrasion can be removed without leaving any residue. Coloured glides or inserts, on the other hand, can leave marks that are difficult or impossible to remove.

The range of floor conditions when choosing a chair glider

- Floor care and floor cleaning

- Floor covering type

- Quality of floor design

It is essential that the cleaning and care of the floor is adapted to the degree of dirt and wear. Small hard grains get stuck in all sliding surfaces and scratch the floor when the chairs are moved and also scratch the sliding surface of the chair gliders. With steel or stainless steel gliders, sharp-edged grooves are created, which in turn attack the floor.

Some floor covering manufacturers seal their floor coverings with a top coat containing corundum to protect the floor covering from scratches. Corundum is a very hard abrasive that quickly wears away gliders and gliding inserts (abrasive effect).

The type of floor covering already determines the friction and adhesion to be expected when moving the chairs and the noise level when moving the chairs. Accordingly, more gliding or more stopping chair gliders and, if necessary, additional noise-damping chair gliders can be selected.

A floor with chairs on it should be even and have no protrusions. Rough floor tiles with protruding edges or abrupt thresholds can quickly render chair gliders useless. In terms of the comfort feature of low noise, a suitable floor covering can already make a decisive contribution.

In many cases, the lifespan of furniture gliders exceeds the useful life of the furniture. Often, a simple, straight glider of our type GL in natural colour or, alternatively, an angled glider of our type RS in natural colour is a simple and satisfactory solution.

Recommendations for choosing the material of the furniture glider

Provided that the flooring is cleaned and treated regularly and at sufficiently short intervals and the chairs are treated with care, the following combinations are conceivable, although this is not an exhaustive list. These combinations have different lifespans for the glide inserts (different levels of comfort) and take into account the sensitivity and slip resistance class:

The bottom can be combined with the following sliding material

Laminate, not sealed with hard material

Soft* to medium-hard felt, TPE, PE, PP, PVC-P (natural colour)

Parquet, not oiled or sealed with a hard material

Soft* to medium-hard felt, TPE, PVC-P (natural colour)

Resilient floor (sports floor)

Stainless steel and natural-coloured (not dyed) medium-hard felt, PA, POM

Linoleum

Soft* to medium-hard felt, TPE, PVC-P (natural colour)

Soft, smooth natural stone

PTFE, TPE, PVC-P (natural colour), soft to medium-hard felt

Soft rough natural stone

TPE, PVC-P

Hard, smooth natural stone

Medium-hard felt, PTFE, PA, PP, PE, POM, PVC-P (natural colour)

Hard, rough natural stone

Each in natural colour (not dyed): POM, PA, PP, PE, PVC-P

Hard, smooth ceramic tiles

Medium-hard felt, PA, POM, PVC-P, TPE

Carpeting/textile flooring

Depending on the type: stainless steel, PTFE, PVC-U (hard PVC)

Vinyl floor

Stainless steel, felt and natural-coloured (not dyed) TPE, PA, PP, PE, POM

Concrete interlocking pavers, exposed aggregate concrete

POM (natural colour), PA (natural colour), stainless steel

Further information on our website

Further information on the sliding materials mentioned in the guide can be found on our website under the menu item Service and

‘Non-binding material information’.

Legal notice

This article was written to the best of our knowledge, but it only represents non-binding views and recommendations of Walter Bethke GmbH & Co. KG.

Walter Bethke GmbH & Co. KG is therefore not liable for any damages that may result from putting it into practice. The coordination of floor material, sliding surface material, colouring of the sliding surface material and surface size of the sliding surface (pressure load) and floor care products must be particularly emphasised. This is to be clarified by the client with the manufacturer of the floor material or specified by the architect.

Copyright © 2025 Walther Bethke GmbH & Co. KG

*) – soft felt is not very durable